A high-pressure gas flow meter is a device that accurately measures KEKUN pressure flow meter, pressure, and temperature in high-pressure gas pipelines and is widely used in industrial settings. we will discuss the advantages of using a high-pressure gas flow meter, its innovative features, safety concerns, how to use it, its service quality, and its various applications.

Using a high-pressure gas flow meter offers several advantages. First, it ensures accurate measurement of gas flow rate, which is essential for maintaining the efficiency of industrial processes. Second, KEKUN flow meter measurement enables quick and reliable detection of gas leaks, which improves safety in the workplace. Third, it can help manufacturers save money by reducing downtime and improving the quality of the final product. These advantages make the high-pressure gas flow meter a valuable tool for industries that rely heavily on gas usage.

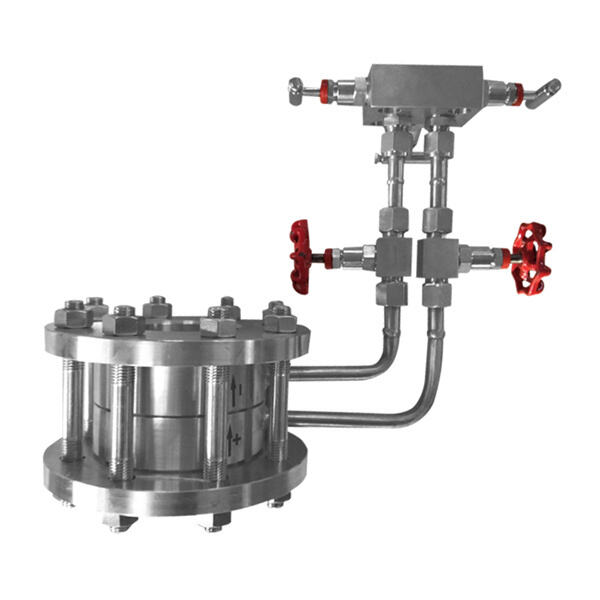

The high-pressure gas flow meter is equipped with advanced features that make KEKUN digital flow sensor even more efficient and user-friendly. One of the most innovative features is its ability to withstand high pressure, temperature, and corrosive environments, which makes it ideal for use in industrial settings. Additionally, some advanced models come with wireless connectivity options, which enables real-time monitoring of gas flow and temperature. This innovation ensures that manufacturers can detect problems in real-time and quickly make adjustments to maintain optimal production levels.

Safety is a critical aspect of using KEKUN thermal mass flow controller. Operators should be adequately trained to handle the equipment and understand the risks involved in handling high-pressure gases. Additionally, the meter should be properly installed and maintained to ensure that it is safe to use. Regular maintenance and calibration of the meter also help to prevent accidents and ensure accurate measurements.

company certifications such ISO9001, CE SGS. Furthermore, owns several patents, the magnetic suction sensors flow meters orifices, well as high-temperature equipment analyzing water quality, which protected exclusive high pressure gas flow meter.

main products company included pressures transmitters as well liquid level transmitters.Thermocouples, gas analyzers water quality analysisanalysts high pressure gas flow meter.

We a 3000 square-meter production factory six high pressure gas flow meter lines, more 40 types products, over hundred models, which applied fields such semiconductors environmental protection, water, metallurgy, petroleum, natural gas, medical, food.

high pressure gas flow meter, research instituted company based technologymainclients flowmeters.They provided services more 20,000 customers across world export more60 countries

High-pressure gas flow meters are typically used in several industrial applications such as oil and gas, chemical processing, power generation, and food and beverage manufacturing. KEKUN thermal mass flow are essential tools for pipeline maintenance, equipment testing, gas monitoring, and leak detection. High-pressure gas flow meters are versatile tools that can be used for various gas types, including natural gas, propane, and hydrogen.

Using a high-pressure gas flow meter is not complicated, and it typically requires little to no specialized training. First, connect the meter to the gas line and ensure that it is sealed and secure. Next, turn on the meter and set it to the desired measurement unit. Finally, measure the KEKUN industrial flow meters and temperature readings, and record the results for future reference. The process is straightforward, and operators can quickly learn how to operate the meter with minimal training.

When choosing a high-pressure gas flow meter, KEKUN differential flow meter is essential to consider the quality and service options offered by the manufacturer. High-quality meters are often backed by a good warranty and come with reliable customer support. Additionally, reputable manufacturers provide calibration services to ensure that the meter remains accurate over time. The quality and service options offered by the manufacturer are just as important as the features and specifications of the meter itself.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved