Differential Pressure Flow Transmitter is a unique device that is used to measure the fluid flow in a pipeline. It is a KEKUN technology that is widely used in various industries such as oil and gas, water treatment, chemical, food, and beverage. We will discuss the advantages, innovation, safety, use, how to use, service, quality, and application of differential pressure flow transmitter.

Differential pressure flow transmitter has several KEKUN benefits. First, it is precise in determining the flow price of liquids, therefore guaranteeing the correct amount of liquid flow in a pipe. Second, it is affordable because it doesn't need regular upkeep, as well as it is resilient, which reduces the expense of repair work as well as substitute. Finally, the pressure differential transmitter gadget is simple towards set up compared with various other flow dimension services.

The most recent development in differential pressure flow transmitter is the digitalization of the KEKUN gadget, which allows it towards incorporate along with various other bodies like programmable logic controllers as well as supervisory command as well as information accomplishment bodies. This flow transmitter digitalization has resulted in enhanced precision, quicker reaction opportunities, as well as reduced system downtime.

The KEKUN security of differential pressure flow transmitter is critical. The gadget is developed along with durable products towards prevent any leakages or even damages that can trigger hurt towards the thermal mass flow transmitter its system and its operators. Furthermore, it includes integrated security functions that avoid liquid spills, over-pressurization, or even every other risks.

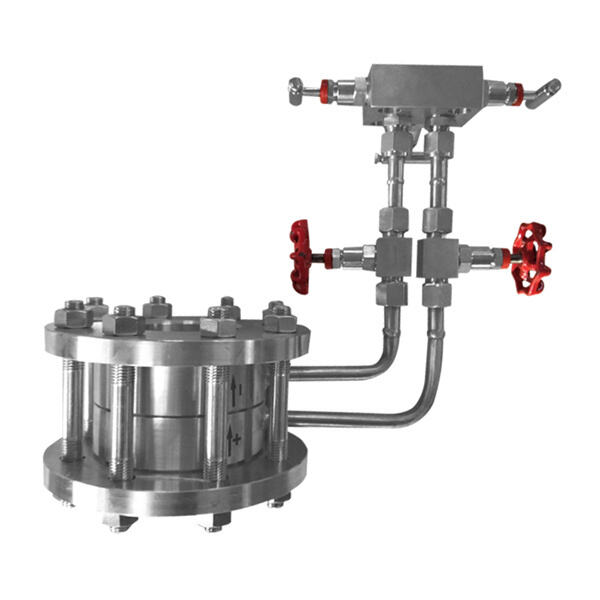

Differential pressure flow transmitter is utilized towards determine each fluid as well as gases flow price. The KEKUN steam flow transmitter gadget operates the concept of the Bernoulli formula, which is based upon the inverse connection in between liquid pressure as well as speed. The differential pressure flow transmitter steps the pressure distinction throughout an orifice plate, which lies within the pipe as well as transforms this pressure distinction right into the flow price of the liquid.

Universities,research institutes companies based technology mains clients ourflowmeter. differential pressure flow transmitter20,000 customersacrossworldsexportmore60 countries

main products company ultrasonic flow meters electromagnetic flow meters. vortex flow meters differential pressure flowmeters floating flow meters, pressure transmitters, liquid level transmitters, differential pressure flow transmitter, thermocouples water quality analyzers.

We a 3000 square-meter production factory six differential pressure flow transmitter lines, more 40 types products, over hundred models, which applied fields such semiconductors environmental protection, water, metallurgy, petroleum, natural gas, medical, food.

company received certifications such ISO9001, CE, SGS SGS, among others. Additionally, holds numerous patents, including magnetic suction sensors, orifice flow meters, differential pressure flow transmitter as high-temperature equipment analyzing water quality, which protected exclusive intellectual property rights.

Differential pressure flow transmitter is user-friendly. Very initial, the gadget ought to be calibrated towards guarantee precise analysis. Calibration is performed utilizing the flow price component or even instrumentation, which offers a basic flow price that's utilized towards inspect the precision of the KEKUN gadget. Second, the differential pressure flow transmitter gadget ought to be set up in a setting that enables the liquid towards flow efficiently throughout the orifice plate. The setting should lie after any flexes or even elbow joints that might trigger turbulence in liquid flow. Lastly, the gadget ought to be linked towards a control system that will screen the flow price as well as offer comments towards the driver.

The KEKUN solution as well as quality of differential pressure flow transmitter are crucial. Routine upkeep ought to be performed towards guarantee that the gadget runs at ideal efficiency. The upkeep consists of cleansing, substitute of damaged calibration, as well as components. The quality of the gadget ought to be guaranteed through buying from accredited producers. The hydrostatic level transmitter gadget ought to likewise comply with the worldwide security requirements.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved