Our products include flow instruments, temperature instruments, pressure instruments, level instruments, analytical instruments, and automation control systems. After years of development, we have served industries such as power, petroleum, chemical, metallurgical, environmental protection, municipal, semiconductor, food, and building HVAC. Our company always adheres to high-quality, high-tech, innovative solutions and reliable services, relying on professional knowledge and experience, To provide services to customers from all over the world.

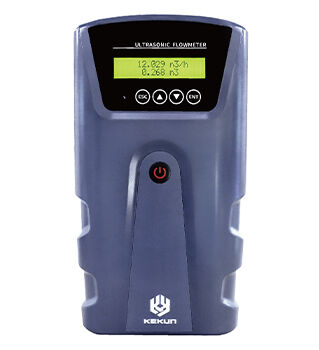

Handheld Flowmeter

Handheld Flowmeter

The handheld ultrasonic flowmeter adopts the principle of time difference measurement, adopts imported core components, is convenient to carry, simple to use, and can be accurately measured anytime and anywhere.

Fixed Flowmeter

Fixed Flowmeter

The fixed ultrasonic flowmeter adopts the principle of time difference measurement, does not cut pipes, does not affect production, and can realize the calculation of flow, cooling capacity and heat consumption.

Differential Pressure Transmitter

Differential Pressure Transmitter

Differential pressure transmitter can be used in petrochemical, metallurgy, electric power and other industrial sectors to detect fluid pressure difference, pressure, density and other parameters.

Pressure Transmitter

Pressure Transmitter

Pressure transmitter can be used in petrochemical, metallurgy, electric power and other industrial sectors to detect fluid pressure difference, pressure, density and other parameters.

Contact us,Please dial:+86 18821150891

View More + Technical team

Technical team

A professional R&D team improves product quality and continuously provides customers with more accurate measuring instruments.

Formulate scheme

Formulate scheme

Based on customer requirements, develop reasonable solutions to save costs while also perfectly solving problems.

Factory shipment

Factory shipment

Factory shipment, cheap price, sufficient inventory, short lead time, less than 50 items shipped within 7 days.

After-sale service

After-sale service

Any after-sales issues can be communicated to us via email or phone, and we will provide feedback within 12 hours. The issue will be resolved within 24 hours to address any concerns or difficulties you may have.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved