Domeniul proceselor industriale este unul în care precizia și eficiența contează mai mult decât orice alt lucru pentru a menține operațiunile la nivelurile optime. Contorii de flux dual au devenit astfel un echipament revoluționar prin care industria gestionează resursele și optimiză procesele pentru o productivitate crescută fiecare zi. Aceste instrumente inovatoare pot să facă ambele lucruri - să măsoare fluxul a două lichide simultan sau să măsoare fluxul și temperatura într-un singur lichid. Disponibile cu monitorizare în timp real și o precizie ridicată, contorii de flux dual au oferit un nou nivel de control al productivității în numeroase industrii.

Abilitatea de a crește eficiența este una dintre multe motive pentru care contorii de flux dual devin din ce în ce mai populari în sectorul industrial. În orice sistem cu lucru industrial neeficient, trebuie să putem controla parametrii critici cu precizie. Contorii de flux dual joacă un rol crucial în acest sens prin oferirea opțiunii de a măsura ambele simultan, reducând costurile senzorilor multipli și eliminând eroarea de la citirea independentă a valorilor. Prin optimizarea sistemului de control al procesului, obțineți timpuri de reacție mai scurte la modificările ratelor de flux, ceea ce duce la o îmbunătățire generală a fiabilității și a eficienței.

Pentru gestionarea precisă a lichidelor, doar câțiva cunosc despre contoarele de flux dual care sunt utilizate pe linia de proces. În acele industrii unde schimbări mici pot avea un impact direct asupra produsului final sau chiar asupra sumelor mari de bani noștri. Aceste contoare oferă măsurători precise, simultane ale volumului și temperaturii în timp real, permițând un control strâns al amestecării, dosării și loturilor. Contoarele de flux dual sunt active cruciale în procesul de producție prin asigurarea calității produselor și reducerea deșeurilor de materiale. În plus, capacitatea de a identifica rapid dacă profilele de flux se abat de la normă poate evita avaria echipamentelor și întreruperile procesului care ar putea altfel să dăuneze produsului dumneavoastră precum și poziției financiare.

Contorii de flux dual folosesc tehnologii de senzori mecanici și electronici combinate pentru a măsura scările de viteză. Pentru procesul în cauză, aceste contoare pot fi bazate pe tehnologii diferite, inclusiv Coriolis, magnetice, ultrasonore sau poate presiune diferențială. Contorii Coriolis, de exemplu, sunt unele dintre cele mai precise contoare de flux și pot măsura fluxul de masă direct folosind acest principiu, făcând din ele o alegere principală atunci când este nevoie de o precizie ridicată. Contorii ultrasonori, pe de altă parte, folosesc unde sunet pentru a determina ratele de flux și sunt neinvazive, ceea ce înseamnă că este necesară o menținere redusă, oferind de asemenea o mare cantitate de compatibilitate cu lichidele. Pentru măsurarea fluxului, înțelegerea capacităților exacte ale tehnologiei unui contor este foarte importantă atunci când se consideră ce fel să se monteze în procesul dvs.

Cu aplicatiile lor variate, contorii de flux dual sunt cu adevărat atât omniprezenti, cât și extrem de necesari în multe industrii. În industria chimică, aceste contoare permit un control precis al rapoartelor de reactanți în sinteză, pentru a obține o uniformitate a produsului și o productivitate generală maximă. De exemplu, contorii de flux dual din industria petrolului și gazei permit monitorizarea dublă a fluxurilor multiphase - o inteligență triplă care face extracția mai eficientă și sigură. În prelucrarea alimentelor și băuturilor, aceștia garantează, la fel, combinarea precisă a ingredientelor - ajutând la menținerea standardelor de gust la cea mai înaltă calitate, în timp ce respectă cerințele stricte de higienă. Integrarea lor cu SCADA & IoT îi face chiar mai valoroși prin permițerea monitorizării la distanță și strategiilor de întreținere predictivă, ceea ce consolidează îmbunătățirea continuă.

Costul investiției în tehnologia de metru de flux dublu nu trebuie să fie alarmant la prima vedere, dar pe termen lung se auto-financează. Aceste metri oferă avantaje semnificative în reducerea costurilor operaționale prin creșterea eficienței procesului, reducerea deșeurilor și diminuarea timpului de întrerupere. Un număr mai mic de instrumente înseamnă costuri mai joase de instalare și întreținere, iar precizia adițională față de numărul total al numărătorilor este extrem de utilă în reducerea pierderii de produs, care poate fi uneori scumpă, în special în procesele cu valoare ridicată. În al doilea rând, acestea protejează mașinaria și procesele dvs. de avarii, ceea ce pe termen lung va rezulta în economisirea costurilor cauzate de reparații sau înlocuirea. Metrii de flux dublu pot fi, prin urmare, văzuți ca o investiție strategică în linia cu mișcarea mai mare pe care industria o face către sustenabilitate și optimizarea resurselor.

Pentru a încheia problema, contorii de flux dual reprezintă un exemplu tipic al modului în care inovația a îmbunătățit procesele industriale. Acești contori revoluționează modul în care gestionarea lichidelor este implementată în diferite sectoare prin permitem măsurarea cu precizie și integrarea unei tehnologii superioare. Sub forma unei control mai bune a proceselor, a unei utilizări mai eficiente și optimizate sau a luării de decizii informate prin date furnizate de contorii de flux dual, avem o cale marcantă către eficiență și profitabilitate mai mare. Cu timpul, pe măsură ce industria se dezvoltă și se schimbă, așa se vor schimba și contorii de flux dual, continuând să sprijine dezvoltarea industrială.

În centrul oricărui proces industrial eficient se află capacitatea de a monitoriza și controla cu precizie parametrii critici. Contorii de flux dual au devenit esențiali în atingerea acestui obiectiv prin oferirea de măsurători simultane, reducând nevoia de dispozitive multiple și minimizând erorile potențiale provenite de la citiri separate. Acest lucru nu numai că simplifică controlul procesului, ci îmbunătățește și timpurile de răspuns la fluturări ale ratelor de flux, îmbunătățind astfel fiabilitatea și eficiența generală a sistemului. Integrarea acestor contoare în sistemele de automatizare amplifică și mai mult efectivitatea lor, permitând industriei să ia decizii bazate pe date în mod rapid.

Precizia este temelia gestionării eficiente a lichidelor, în special în procese în care chiar și deviații mici pot duce la incoerență a produsului sau la pierderi. Contorii de flux dual joacă un rol crucial aici prin oferirea unei măsuri simultane și în timp real atât a volumului, cât și, în unele cazuri, a temperaturii. Această dublă capacitate asigură un control strâns asupra operațiunilor de amestecare, dozare și lotificare, menținând calitatea produsului în timp ce se reduc pierderea de materiale. Mai mult, abilitatea lor de a detecta anumale în modelele de flux rapid poate preveni daunele echipamentelor sau discontinuitățile procesului, protejând atât produsul, cât și rezultatele financiare.

La baza funcționalității contorilor de flux dual se află o combinație sofisticată de componente mecanice și electronice concepute pentru a măsura ratele de flux cu precizie. În funcție de aplicație, acestea pot utiliza tehnologii diferite, cum ar fi Coriolis, magnetice, ultrasonice sau presiune diferențială. Contorii Coriolis sunt de exemplu foarte precizi și pot măsura fluxul de masă direct, făcându-i ideali pentru aplicații care necesită o precizie ridicată. Contorii ultrasonici, pe de altă parte, folosesc unde sunor pentru a calcula ratele de flux fără a intra în contact cu lichidul, minimizând nevoile de întreținere și permițând o compatibilitate largă cu diverse lichide. Înțelegerea tehnologiei specifice fiecărui contor este cheia selectării celui mai potrivit pentru un anumit proces.

Versatilitatea contorilor de flux cu dublu sens a făcut ca aceștia să fie indispensabili în numeroase industrii. În industria chimică, ei facilită controlul precis al rapoartelor de reactanți în timpul sintezei, asigurând consistența produsului și maximizând rendita. În petroliere și gaz, ei ajută la monitorizarea fluxurilor multiphase, sporind eficiența extragerii și siguranța. Similar, în prelucrarea alimentelor și băuturilor, ei asigură amestecul precis al ingredientelor, păstrând gustul și calitatea, în timp ce se respectă standardele stricte de higiene. Capacitatea lor de integrare cu sistemele SCADA și IoT consolidează mai mult valoarea lor, permitând monitorizarea la distanță și strategii de întreținere predictivă care promovează îmbunătățirea continuă.

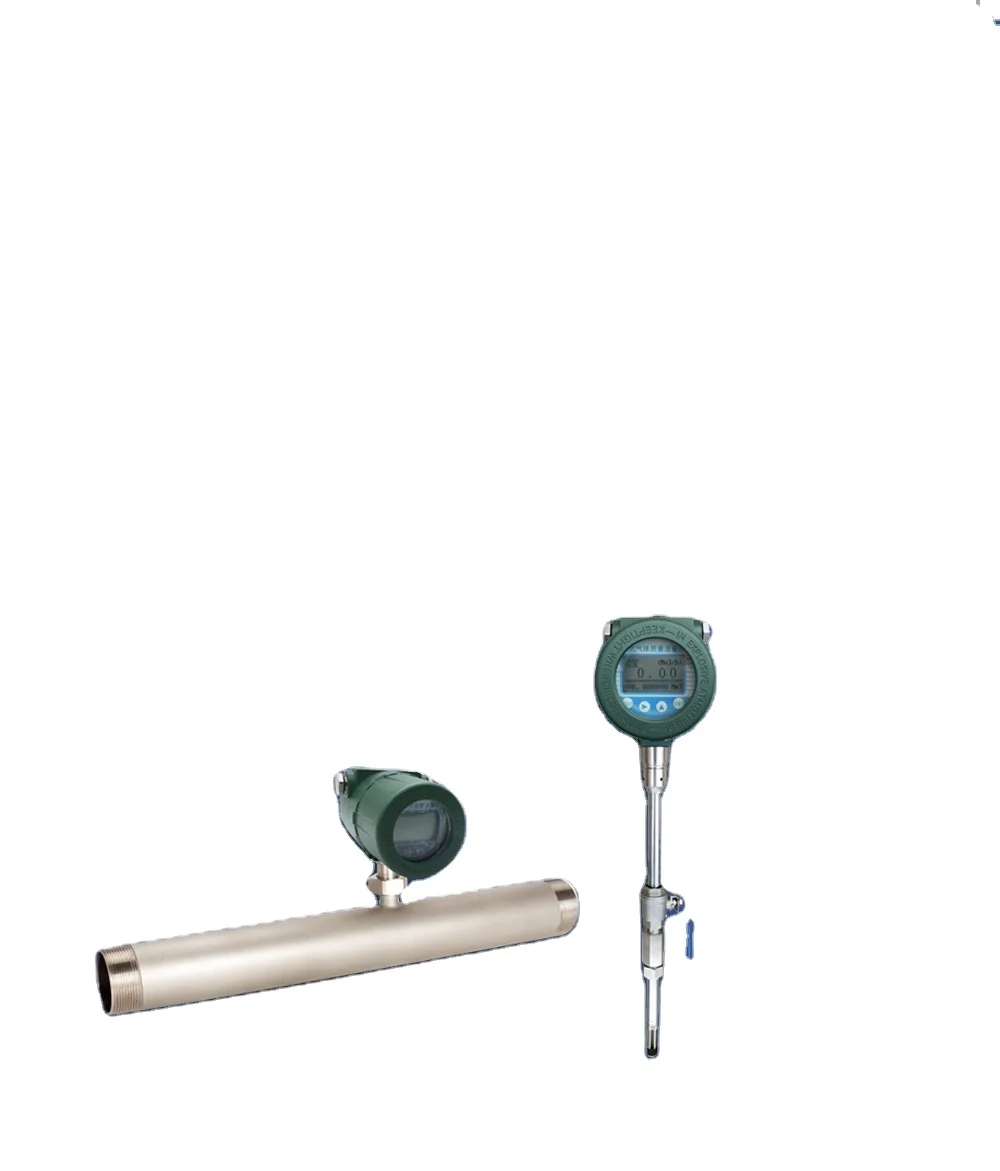

produse contor de flux dual companie contoruri ultrasonice de flux contoruri electromagnetice de flux. contoruri de flux vortex contoruri de flux cu presiune diferențială, contoruri de flux cu flotare, transmițătoare de presiune, transmițătoare de nivel de lichid, termopereche, analizatoare de gaze, analizatoare de calitate a apei.

contor de flux dual fabrică de producție de 3000 metri pătrați, șase gamuri de produse, peste 40 de tipuri de produse și mult mai mult de o sută de modele sunt utilizate în domeniile semiconductoarelor, apei, protecția mediului, metalele, petrolul, gazul natural, medicina și alimentele.

Universitățile, instituții de cercetare și companii bazate pe tehnologie sunt clienții principal pentru contorii noștri de flux dual. Mai mult, clienții noștri ai contorului de flux dual se află în întreaga lume și exportăm în 60 de țări.

compania a obținut certificări precum ISO9001, CE, SGS și altele. Detine un număr de brevete pentru senzori magnetici cu sugeție, contorii de flux cu orificiu și contorii de flux dual, precum și echipamente de analiză a calității apei, care sunt protejate prin drepturi intelectuale independente.

Deși investiția inițială în tehnologia de metru de flux dual poate părea semnificativă, beneficiile pe termen lung depășesc cu mult costurile inițiale. Prin îmbunătățirea eficienței procesului, reducerea deșeurilor și minimizarea timpului de întrerupere, aceste metri contribuie semnificativ la economii operaționale. Nevoia mai mică de instrumente reduce cheltuielile de instalare și menținere, iar precizia îmbunătățită minimizează pierderea produselor, ceea ce poate fi deosebit de costisitor în procese cu valoare ridicată. Mai mult, rolul lor în prevenirea daunărilor la echipamente și a ineficiențelor procesului se traduce în economii indirecte legate de reparații și înlocuiri. Pe măsură ce industriile se concentrează din ce în ce mai mult pe sustenabilitate și optimizarea resurselor, metrul de flux dual merge în evidență ca un investiție strategică care se aliniază cu aceste obiective.

În concluzie, contorii de flux dual reprezintă un testimon al puterii inovării în ameliorarea proceselor industriale. Prin combinarea măsurătorii precise cu sofisticarea tehnologică, acestea transformă practicile de gestionare a lichidelor în diferite sectoare. Indiferent dacă este vorba de îmbunătățirea controlului procesului, optimizarea utilizării resurselor sau facilitarea luării deciziilor bazate pe date, aceste contoare demonstrează o cale clară către creșterea eficienței și profitabilității. Pe măsură ce industria continuă să evolueze, contorii de flux dual vor rămâne cu siguranță un pilon al infrastructurii industriale moderne.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved