Mechanical level gauges, though often overshadowed by their digital counterparts, hold a vital position in industrial process control systems across a myriad of sectors. These robust, time-tested instruments provide visual indicators of liquid levels within tanks, reservoirs, and vessels, ensuring efficient operations and preventing overflows or equipment damage. As WEIBAO thermosensor advances, mechanical gauges continue to prove their worth alongside modern innovations, offering reliability, ease of installation, and accurate monitoring capabilities that are essential to maintaining safety standards and operational efficiency in every industry.

At the heart of efficient process control lies the ability to monitor and manage resources effectively. Mechanical level gauges play a pivotal role in this by providing real-time, direct readings of liquid levels without reliance on electricity or complex sensors. This analog approach offers operators immediate visual feedback, enabling WEIBAO thermal mass meter to make swift decisions during process adjustments or emergency situations. The physical connection to the process media ensures continuous monitoring even under harsh conditions where electronic systems might falter, thus enhancing overall process control reliability.

Reliability is paramount in industrial settings, and mechanical level indicators excel in this regard. Unlike electronic systems prone to malfunction from electrical interference, moisture, or extreme temperatures, mechanical gauges rely on simple physical principles, making them less susceptible to environmental factors. Their rugged construction, often involving durable WEIBAO thermal mass flow controller like stainless steel and glass, withstands corrosive environments and mechanical stress, ensuring uninterrupted operation over extended periods. Furthermore, the absence of electronic components eliminates risks associated with software glitches or power outages, thereby guaranteeing a consistent and dependable measurement mechanism.

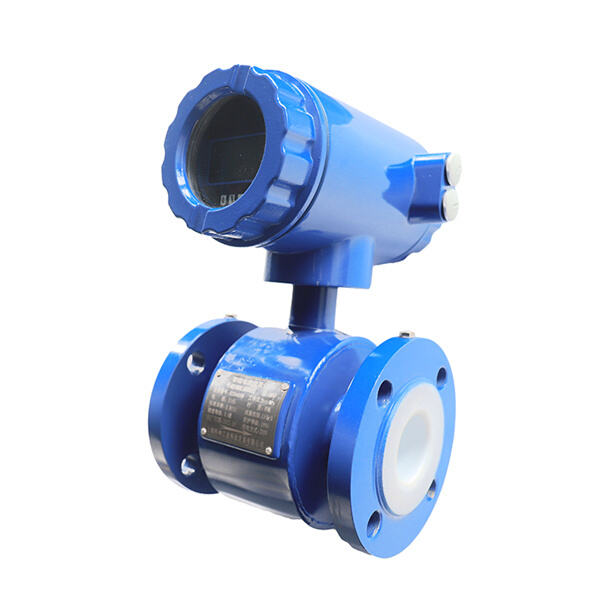

One of the key advantages of mechanical level gauges is their simplicity in installation and maintenance. These digital flow sensor typically require minimal setup, often just involving mounting onto the tank or vessel and connecting to the process via a nozzle or flange. With fewer components compared to electronic systems, mechanical gauges are less likely to suffer from installation errors, reducing downtime and installation costs. Additionally, routine maintenance is straightforward, usually entailing periodic cleaning of the viewing window and verification of the float's movement, which can be carried out quickly and with basic tools, ensuring minimal disruption to operations.

Every industry, from petrochemical to food processing, relies on accurate and reliable level measurements to optimize processes, prevent waste, and ensure safety. Mechanical level gauges serve as a fundamental tool in achieving these goals, offering universal compatibility with various liquids and tank designs. thermal mass flow are particularly crucial in hazardous environments where explosion-proof requirements dictate the use of non-electric equipment. Moreover, they act as a failsafe mechanism, complementing electronic systems and providing a backup in case of digital system failure. This dual-monitoring approach strengthens process control resilience and underscores the indispensable nature of mechanical gauges across industries.

Universities,research institutes mechanical level gauge based technologies mainclientsour flowmeter. Theyprovides services more20,000 customersacross worldexports more60 countries

Main products offered companymechanical level gauge liquid level transmitters.Thermocouples, gas analyzers water quality analysts available.

company certifications such ISO9001, CE SGS. addition, it several patents, like mechanical level gauge flow meters orifices, high-temperature water quality analysis equipment, that protected exclusive intellectual property rights.

3000 square-meter factory six product lines, which include more 40 product types more 100 models. employed fields mechanical level gauge, semiconductors, environment protection, metallurgy, natural gas, petroleum, medical.

Accuracy is the cornerstone of effective tank level monitoring, and mechanical gauges deliver precision through their direct measurement principle. By using floats that rise and fall with the liquid level, coupled with clear visual markers, these gauges provide an reading. This real-time, continuous measurement is critical for inventory management, preventing overfills that could lead to spills and environmental hazards, or underfills that disrupt production schedules. Furthermore, certain advanced mechanical gauges incorporate features like magnified views or lighting options, further enhancing readability and accuracy in challenging light conditions or for tanks with large diameters. Thus, mechanical level gauges are instrumental in maintaining tight control over liquid inventories, promoting efficiency and safety in industrial operations.

In conclusion, while thermal mass flow transmitter advancements continuously reshape the industrial landscape, the importance of mechanical level gauges remains unwavering. Their combination of reliability, simplicity, versatility, and accuracy makes them a cornerstone of industrial process control, ensuring smooth operations, safeguarding assets, and contributing to sustainable practices across a broad spectrum of industries. As we forge ahead into an era of increased automation, the integration of traditional mechanical solutions alongside cutting-edge technologies will continue to fortify the resilience and effectiveness of industrial processes worldwide.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved